Quality Control

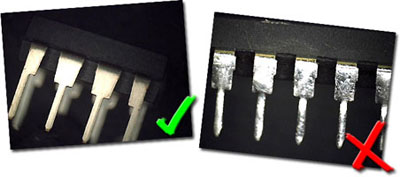

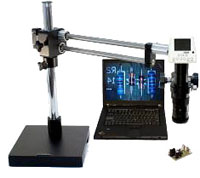

OMO Electronic limited invests substantial resources into building and improving our industry leading quality control and inspection processes. From state of the art equipment to the quality engineers that complete the inspection process, OMO Electronic limited devotes substantial resources to ensuring quality. We rely primarily on vendors with whom we have long-standing, trusted relationships and scrutinize any potential new vendors before we agree to conduct business with them. OMO Electronic limited employs a rigorous inspection process to ensure that only the highest quality product leaves our dock. In addition, OMO Electronic limited utilizes documented and audited receiving processes which include photographs of all material under microscope. Our professional, trained staff and state-of-the-art inspection equipment along with a secure, climate/static controlled environment, ensures that every part is handled with the highest quality standards.

At OMO Electronic limited every part goes through our strict QC process:

1.Hi-powered microscope inspection of all parts.

2.Validation against manufacturer’s datasheet, as well as industry databases.

3.Acetone testing throughout the entire lot.

4.Measurement of parts with microscope and specialized software to ensure measurement accuracy.

In addition, we have established relationships with various independent test houses, should you require testing of parts before shipment.